|

|

|

|

|

|

Lithium Batteries for 6V Vintage Bikes By LoneStar

Most British bikes prior to 1960 were supplied originally with hard-rubber case 6V batteries from makers such as Lucas, Exide and Varley.

These are usually visible, unlike on later bikes. Original

batteries are difficult or impossible to find these days, and simply installing a modern one looks a bit goofy. A common

solution is to use either a gutted original battery or a replica case, with a modern battery inside.

This has been my practice, and it works reasonably well. As the modern battery has to be smaller, to fit in the case, it usually has lower capacity

than the original - but this rarely causes problems. I've used the Powersonic PS-682 (6V 9AH) with good results, and it fits easily into

a standard hard rubber case. This is an Absorbent Glass Mat (AGM) sealed battery, mostly used for alarm systems.

While AGM batteries hold their charge better than traditional flooded lead-acid ones, they still require periodic recharging

if the bike isn't ridden. If you forget this and the voltage drops too low, the battery will not recover. Also, vintage bikes

sometimes vibrate a bit (!), which can cause internal damage. This happened to me recently on a BSA Gold Star - no power, but it would

come back briefly if you slapped the battery case and restored the internal connection.

So, I thought it would be interesting to explore an alternative to the AGM, namely lithium iron phosphate (LiFePO4) batteries. The idea

was proposed on the VOC forum by user "oexing". Note these are a

different chemistry to the lithium ion batteries used in cell phones and elsewhere.

Important differences:

There are several advantages to LiFePO4 batteries over AGM:

All very promising, but I was unable to find a suitable 6V LiFePO4 battery. Antigravity makes one that might be squeezed into

a vintage hard-rubber case - but a 6V 10AH version retails for $180. Being cheap, I decided to make my own.

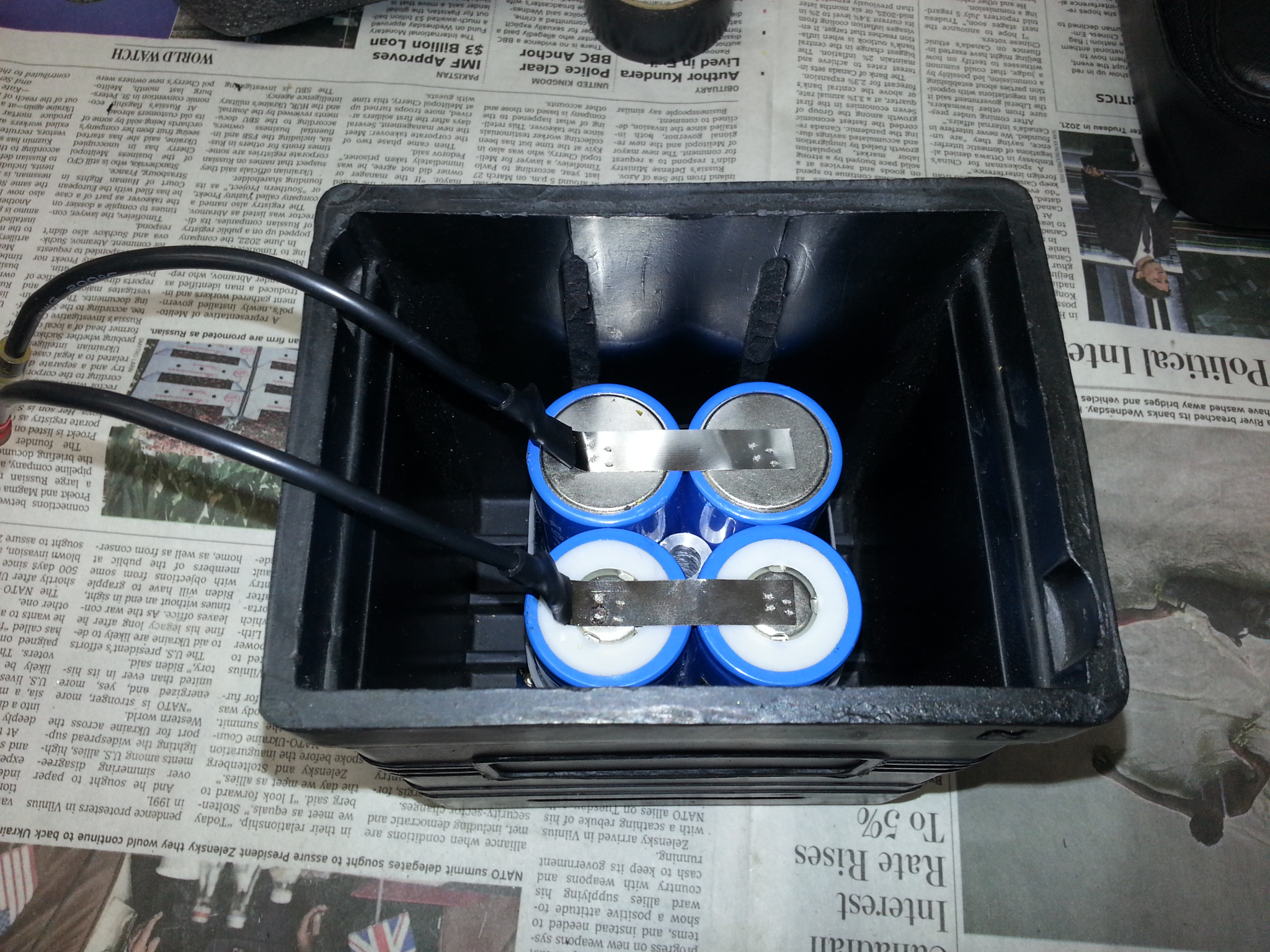

I chose LiitoKala 70A 32700 LiFePO4 cells - 32mm diameter x 70mm long.

These are 3.2V and

claimed to be 7AH capacity, though a more conservative estimate would be 6AH. An array of 4 cells

wired as sets of 2 in parallel, with 2 of those sets in series, results in a 6.4V 12AH battery - perfect. Note you could probably get by using only two

cells instead, wired in series. The resulting 6AH would be adequate for most use on an old bike with limited electrical draw. But with plenty of room in the case,

and not much extra expense, I opted for the higher capacity of 4 cells.

The 32700 cells are available in the US, but scarce - I found it easier to buy them from the "liitokala Official Store" on AliExpress in China.

Four cells with shipping cost $26 (as of late 2023). While you can buy individual cells, I chose an array of 4 connected in parallel, thus

rated as 3.2V 28AH. The advantage is that the cells are connected with welded-on nickel strips, making it easier to wire them.

I inserted a small tube in the center of the four cells, to hold them in a square alignment, then wrapped the assembly in 150mm PVC heat shrink tubing

(available on Amazon).

If you prefer to use a BMS, they're also available on AliExpress for around $3 - look for one labeled "Lifepo4 2S 6.4V 15A".

The scheme outlined here could be used to build a 12V LiFePO4 battery, but I haven't tried it. There isn't room in a

hard-rubber case for 8 32700 cells, so it would be necessary to use 4 cells in series for 12.8V with 6AH capacity. This might be fine for many setups,

though certainly not for an electric start. Or possibly smaller LiFePO4 cells can be found, to fit 8 cells in the box (4 series x 2 parallel)

and give greater capacity.

|

|

|

|

|

|