|

|

Extraction Fun

(with much help from a friend)

By Bev Bowen

Back in July, some of you will recall I had maximum fun joining in on an “Epic Ride” in the

Smokey Mountains, then ending up at The Barber Museum in Birmingham, which included

semi-hot laps around the splendid race course, there.

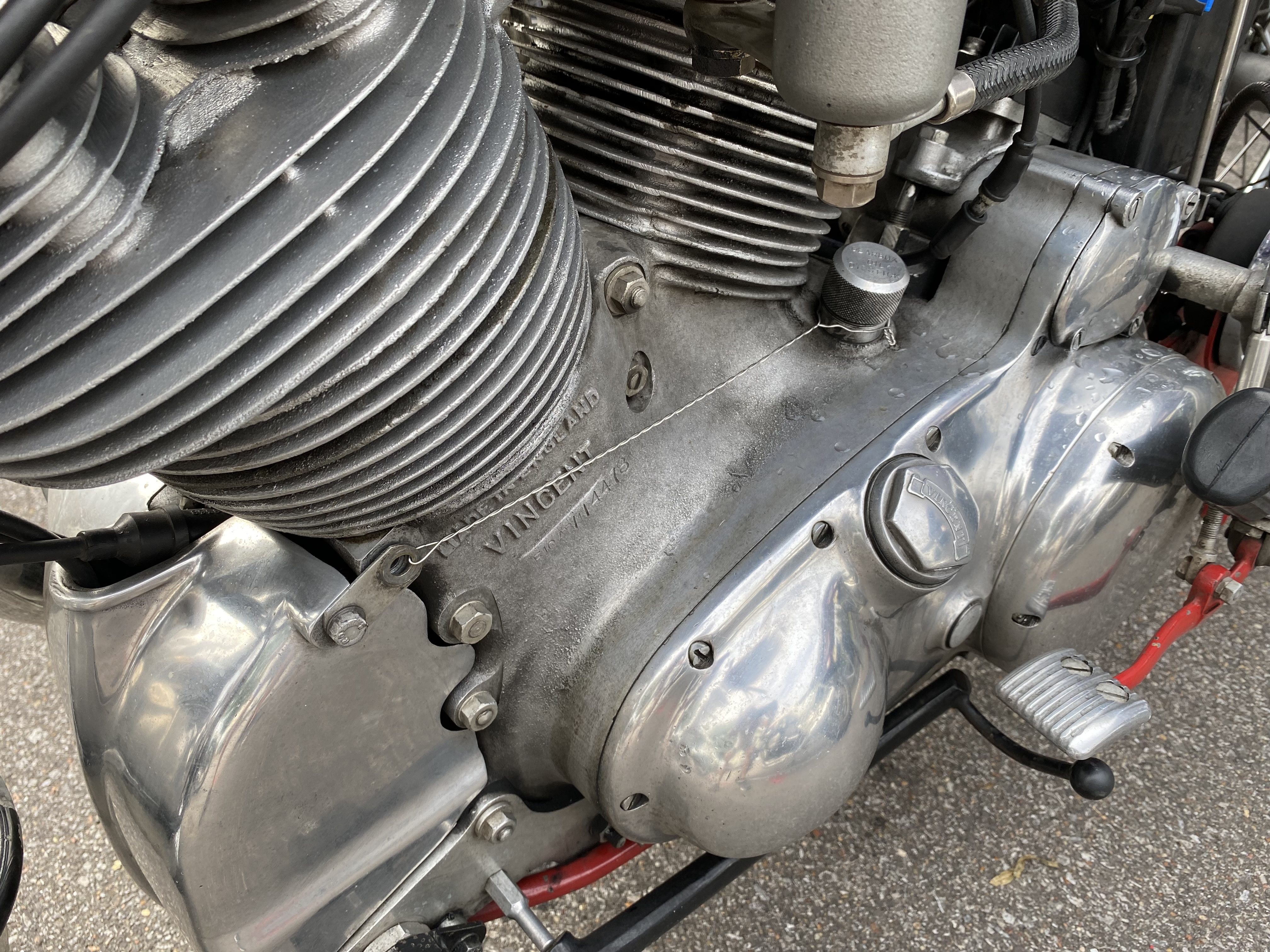

Well, my ride was pretty much trouble-free, as trusty “Thunder,” my 1950 Red Rapide, snarled

about on the gnarly mountain roads and commute to B’ham. One day, though, we were riding

the Cherohala Skyway, and stopped at a beautiful scenic view rest stop. As we resumed our

ride, I heard and felt a hard hit from some object in the road which struck my rear mud guard. I

recall making some comment inside my helmet, but motored on, feeling no damage had been

done.

When we arrived at our destination for the evening, I noticed the stud on the left engine case,

the one that also serves to secure the tab for the upper left magneto cowl, was GONE! Argh!

That was no doubt what I had hit on the road! A close look with a flashlight revealed the stud

had snapped, leaving about an inch of thread deep in the case.

I figured the cases would not come apart with just that bit unfastened, but I was concerned

that the cowl might become loose and hit the mudguard. So, I rummaged through the tools in

our chase trailer and found safety wire and pliers. A pal on the ride, a racer, is an expert with

safety wire, so I asked him to kindly secure the magneto tab to the gear oil filler cap. With that,

I had no problem at all completing the ride.

Safety wire saves the day

Once at home, I set to a repair. Consulting Vincent Men here and abroad with phone calls,

emails and VOC forum chat, I got a variety of advice, including to “split the cases!” Most

everyone agreed with me, though, that extraction was possible, but would involve special

tools, none of which I had or could make (all y’all know I ain’t got a lathe and don’t know how

to weld!).

My memory led me to the SOURCE! Yes, a number of years ago Miss Gail and I had occasion

to tour the Great Northwest on our GoldWing and I got in touch with John Hanson, the noted

VOC member who had recently (then) fully restored the former Tommy Auger Black Lightning.

He was also then a recent retiree to a lovely and remote place on the Washington Peninsula.

So, he met us for lunch on his own GoldWing and we headed for his MAGNIFICENT shop,

where we got a thorough tour of his machines, projects, and TOOLS! Wow! he even makes his

own tools, then makes an elegant wooden box for their safe-keeping. Just a great Vincent Man

and very talented.

So, I rang him up and sure enough, he had the tools I needed, and some precise instructions

how to se them. These were all extended reach - a 5/16” brass sleeve to ensure proper

guidance, a center punch, two drills (one a pilot, the other to complete the job), and two

extractors (in case one failed). Also, he threw in a larger drill in case I failed, to chew up the

stubborn broken piece, and a tap to renew.

The right tools for the job

Fortunately, with John’s good instruction and tools I was quickly successful. I had ordered a

new stainless stud from Coventry. These repop studs are unlike the originals not only because

they are stainless, but because they do not have the slot for screwdriver, and they are a bit

LONGER on the BSF (outer) threaded portion. At this point in my Vincent walk, I am not so

particular about originality, so I did not shorten the stud and create a screwdriver slot, nor did I

bead blast the stainless to make it look cadmium! Bah! I also took advantage of extra length to

“double nut” the stud, which not only was how I drove the stud in but also serves as a safety

feature for keeping the stud secure. I did use anti-seize compound on the Whitworth (inner)

threads. John suggested the original studs, being shouldered, were prone to snapping at that

weak spot where there are no threads close to the shoulder.

Anyway, from the photos, you can see the progression from missing stud to finished repair,

along with the tools John sent. I did quickly return them, BTW!

Fixed

As we say, a lot of successful mechanic work is about having the right tool. It’s also helpful to

have knowledgeable and generous pals. John is a great example of the good folks we have

within the VOC! With his help a possibly complicated repair was made easy.

|

|